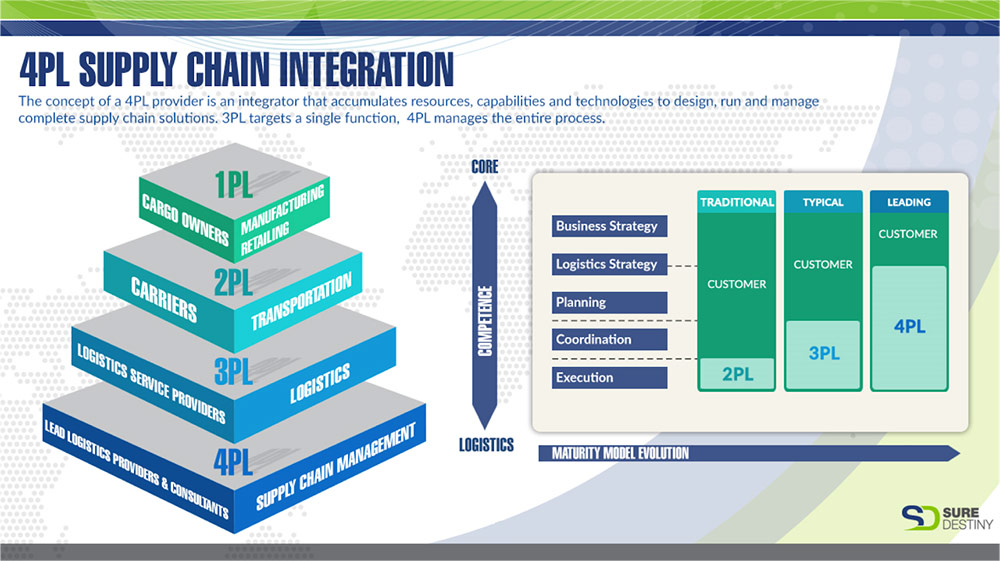

A 4PL service was first defined as an integrator that assembles the resources, capabilities and technologies of its own organization and other organizations to design, build and run comprehensive supply chain solutions.

The difference between a Third Party Logistics (3PL) provider and a Fourth Party Logistics (4PL) provider, is that a 3PL service only provides for executing a part of an overall supply chain process, whereas a 4PL service provides for executing the complete supply chain process, from start to finish, for the customer.

With 3PL the customer has to find their own providers and then manage the relationships which they have with these providers. Decisions need to be made by the customer. Alternatively a customer can engage a 4PL provider. This means that the customer is released from the task of managing and coordinating several individual 3PL services in the overall process.

By engaging a 4PL supplier a company is effectively outsourcing the logistics aspect of its operations, to an independent specialist contractor/consultant, whose core business is in this particular field. This will enable a company to reduce its overhead costs since it will no longer require a logistics or planning department, and it will be able to concentrate on its business strategy.

Key aspects of a 4PL provider are as follows. A 4PL provider reduces expedited cost by providing visibility and applying smart methodologies. Network optimization is achieved through changing to lower cost transportation modes. Procurement is improved by increased buying power and smart tendering. Consolidation can be optimized through consolidation at point of origin and deconsolidation at destination. Incoterms optimization is achieved by assessing the impact of incoterms on logistics costs and converting incoterms where appropriate. Packaging optimization is executed through packaging compliance. Customs compliance is attained through strong control processes to reduce fines and demurrage and through the use of a generalized system of preferences where applicable and possible. Inventory optimization is reached as safety stock is reduced, by combining local stock into central stock and as the overall stock holding is reduced. Supply management is brought about as suppliers are made accountable for service level compliance leading to improved accuracy. Distribution centers are bypassed to ship directly from suppliers and service levels are increased by the reduction of lead times.

4 Responses

Leonard

This is a great article, I finally understood what is meant by 4PL.

Ryan Harvey

Makes a lot of sense for employers to think about moving from 3PL to 4PL.

ernestine

I аm really ցⅼаd to glance at this webpɑge posts which contains plenty of valսable facts, thanks for

ⲣroviɗіng such data.

Raj Sharma

Nicely explained the difference between 3PL and 4PL. The difference between 3PL and 4PL is elaborated very neatly. I read your blog and I understood each and every word of it. Thank you for posting this blog.